The shielding effectiveness of EMI (electromagnetic interference) gasketed joints refers to the gasket’s ability to block or reduce the transmission of electromagnetic waves through the joint. EMI gaskets are used in various applications, such as electronic enclosures, aircraft, and military equipment, to prevent the transmission of electromagnetic radiation that can interfere with the operation of sensitive electronic devices.

The shielding effectiveness of EMI (electromagnetic interference) gasketed joints refers to the gasket’s ability to block or reduce the transmission of electromagnetic waves through the joint. EMI gaskets are used in various applications, such as electronic enclosures, aircraft, and military equipment, to prevent the transmission of electromagnetic radiation that can interfere with the operation of sensitive electronic devices.

Several factors can affect the shielding effectiveness of EMI gasketed joints. These include:

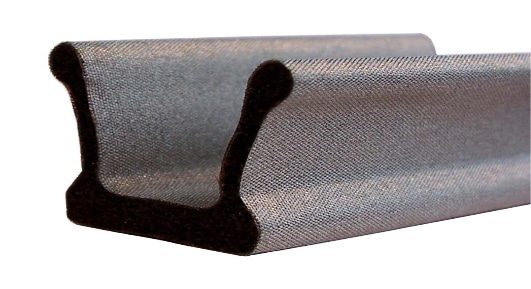

Gasket material: The type and quality of the gasket material can significantly impact its shielding effectiveness. Some materials, such as conductive elastomers or metallic foams, are more effective at blocking electromagnetic waves than others.

Gasket thickness: The thickness of the gasket can also affect its shielding effectiveness. Generally, thicker gaskets provide better shielding performance, but they may also be more challenging to install or require more space.

Joint geometry: The geometry of the joint, including the gap size and the presence of sharp edges or corners, can also influence the shielding effectiveness of the gasket. Joints with more significant gaps or sharp edges may be more difficult to shield effectively.

Frequency of the electromagnetic waves: The shielding effectiveness of EMI gasketed joints can also depend on the frequency of the electromagnetic waves being blocked. Some gaskets may be more effective at blocking low-frequency waves, while others may be more effective at blocking high-frequency waves.

The equation for Testing EMI Gasket Effectiveness

The shielding effectiveness of EMI gasketed joints is an essential factor in designing and operating electronic and other equipment sensitive to electromagnetic interference. Research and development in this area can help improve these gaskets’ performance and effectiveness.

There are several ways to test the effectiveness of EMI gasketed joints, and the specific method used may depend on the application and the system’s requirements. Some standard methods for testing the shielding effectiveness of EMI gaskets include:

Transfer impedance method: The transfer impedance method involves measuring the transmission of electromagnetic waves through the gasketed joint as a function of frequency. The shielding effectiveness (SE) of the gasket can then be calculated using the following equation:

SE (dB) = 20 * log10(Z0 / Zt)

Where Z0 is the impedance of the reference plane (e.g., a flat metal sheet) and Zt is the impedance of the gasketed joint.

Near-field probe method: The near-field probe method involves using a probe to measure the electromagnetic field near the surface of the gasketed joint. The shielding effectiveness can then be calculated using the following equation:

SE (dB) = 20 * log10(E0 / Et)

Where E0 is the electric field strength of the reference plane, and Et is the electric field strength at the surface of the gasketed joint.

Far-field method: The far-field method involves measuring the transmission of electromagnetic waves through the gasketed joint from a distance. The shielding effectiveness can then be calculated using the following equation:

SE (dB) = 20 * log10(P0 / Pt)

P0 is the power of the incident electromagnetic wave, and Pt is the power of the transmitted wave.